The Study on Resolution Factors of LPBF Technology for Manufacturing Superelastic NiTi Endodontic Files

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

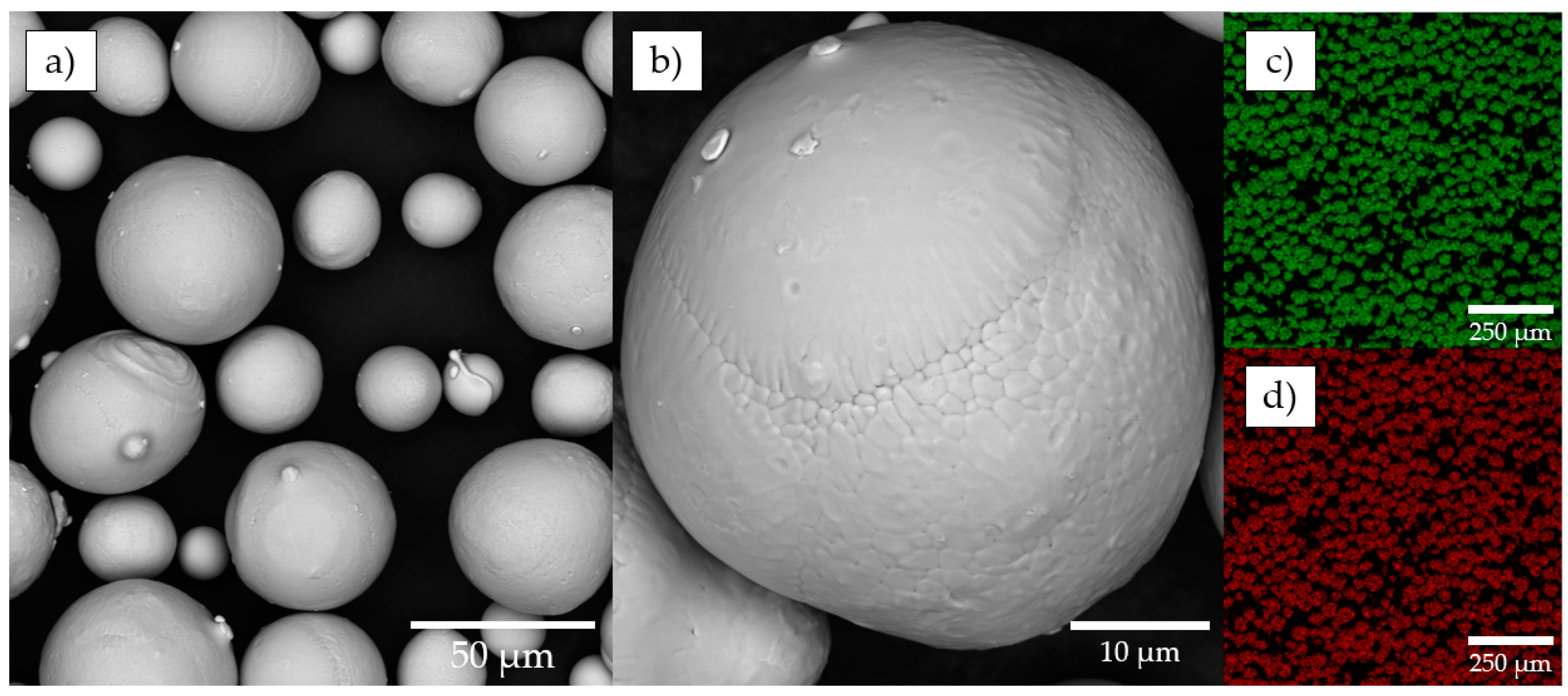

3.1. Raw Powder Characterization

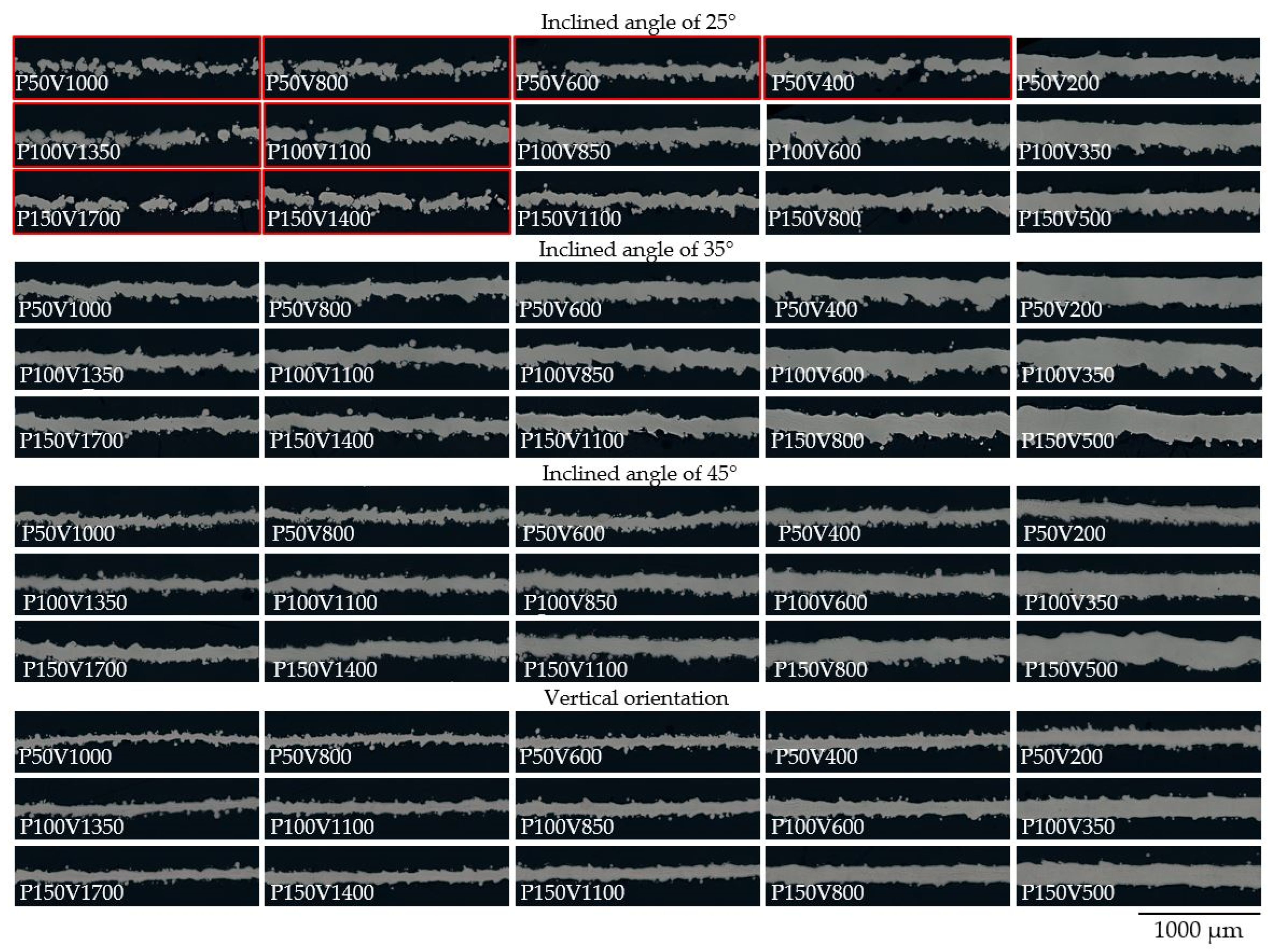

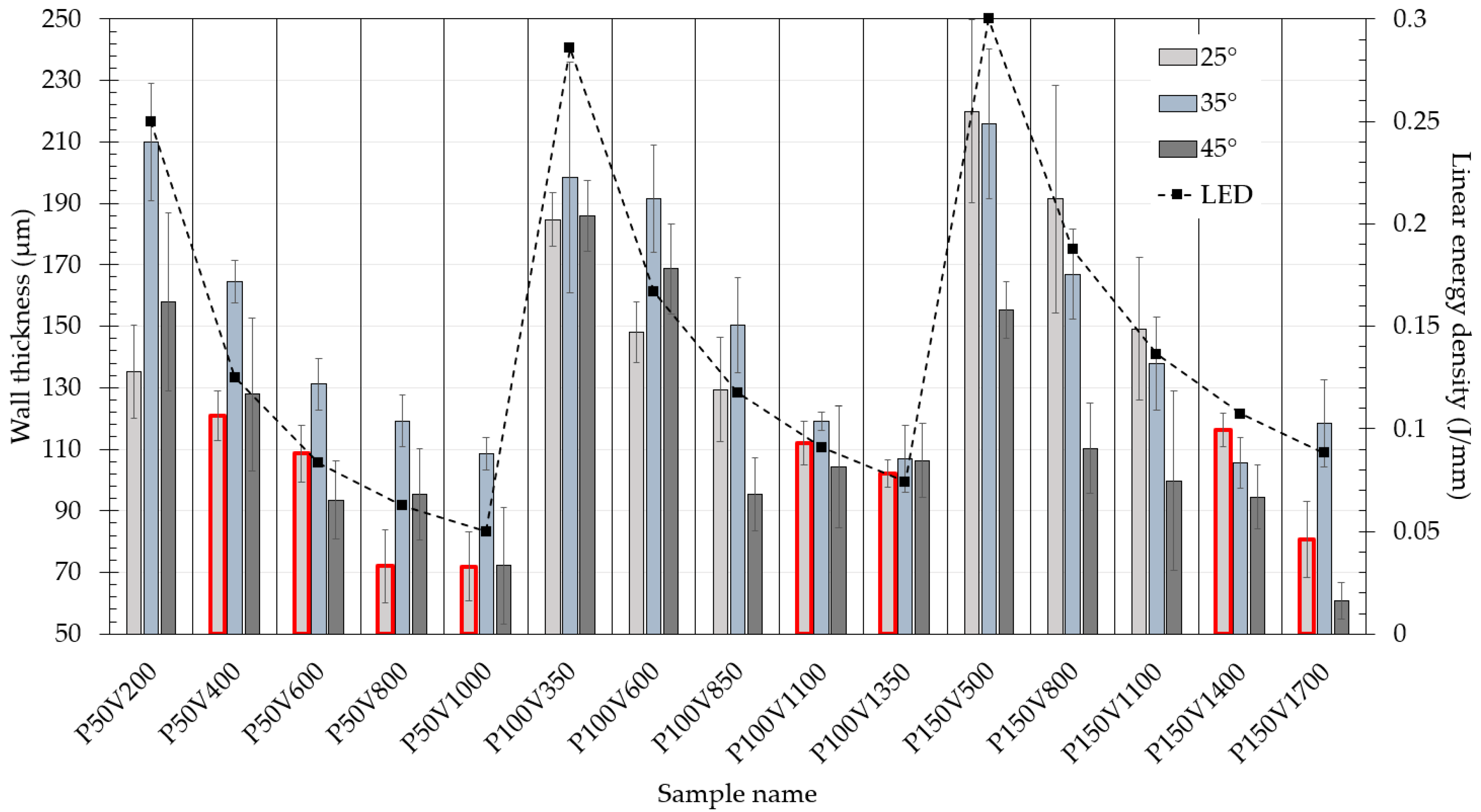

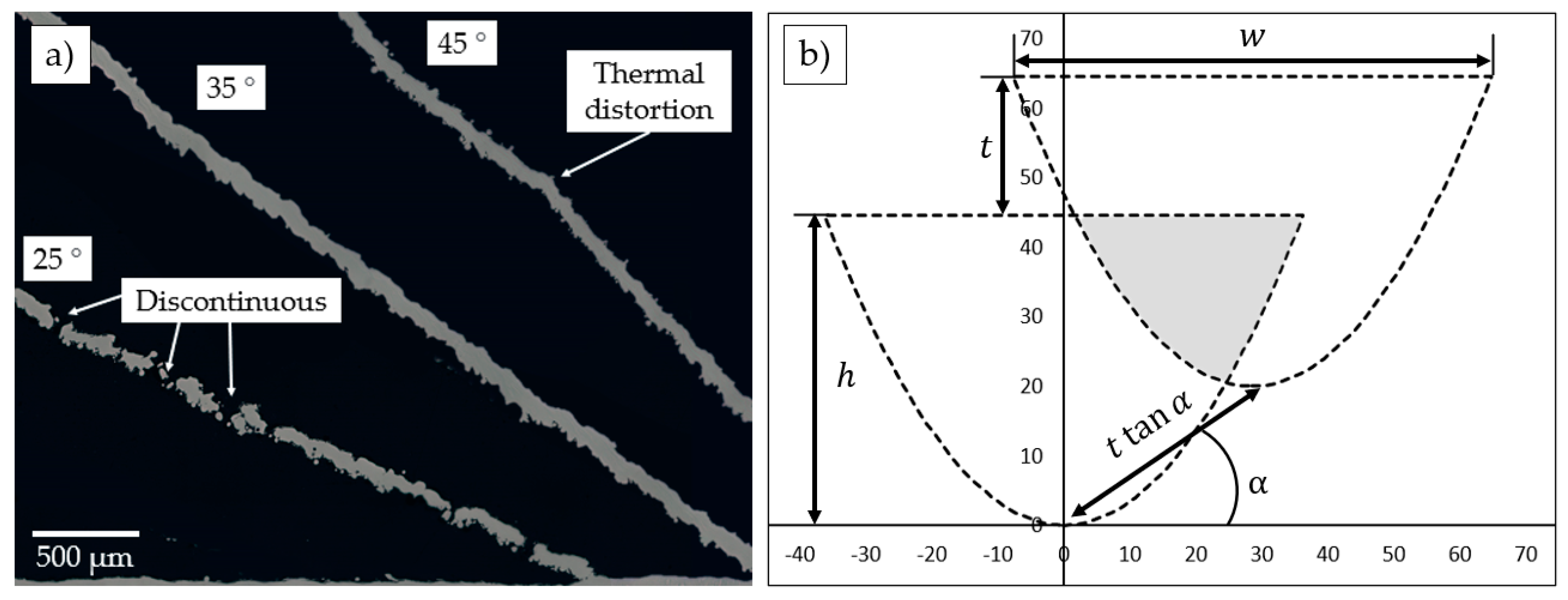

3.2. Single Track Based Thin Walls

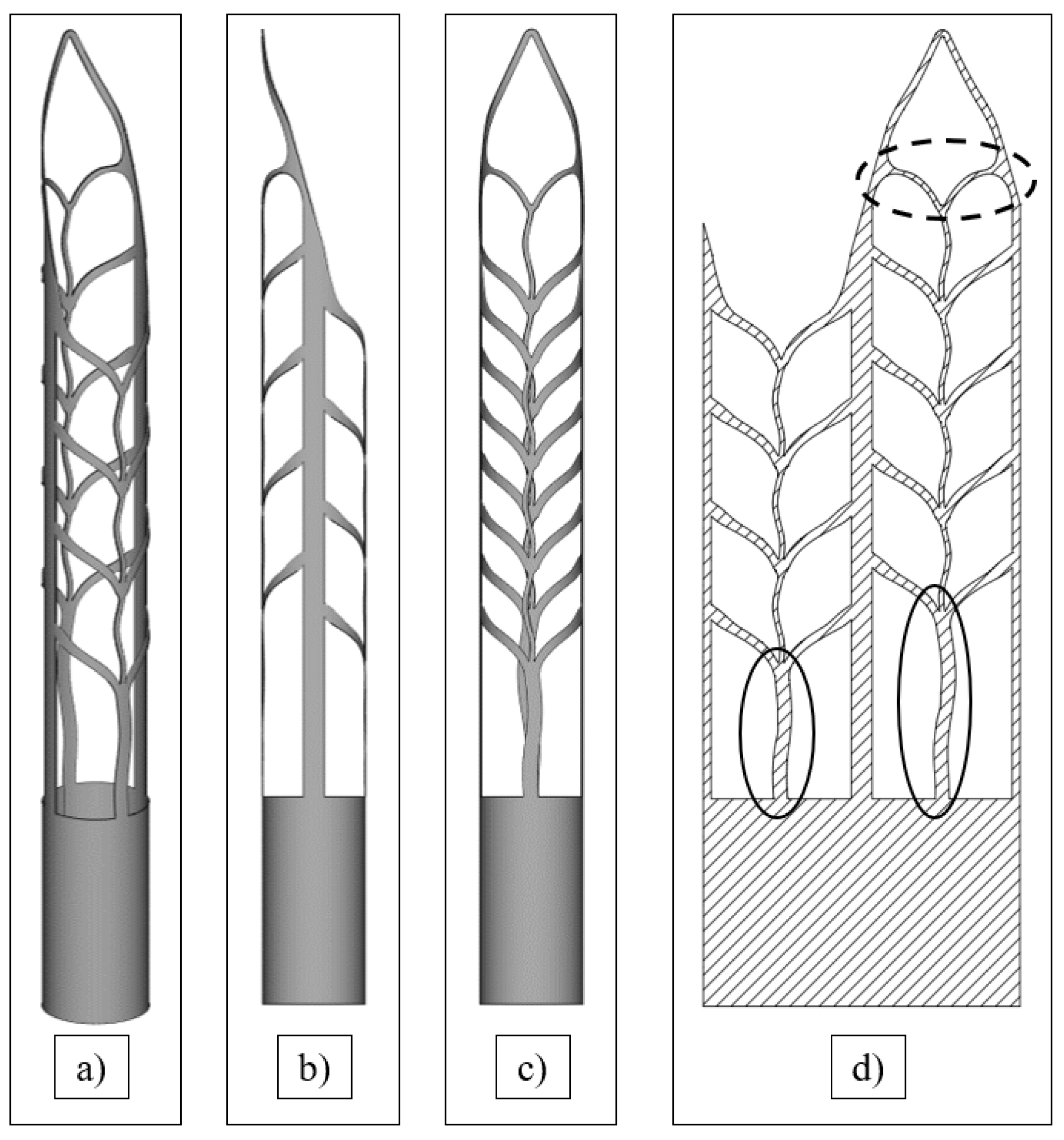

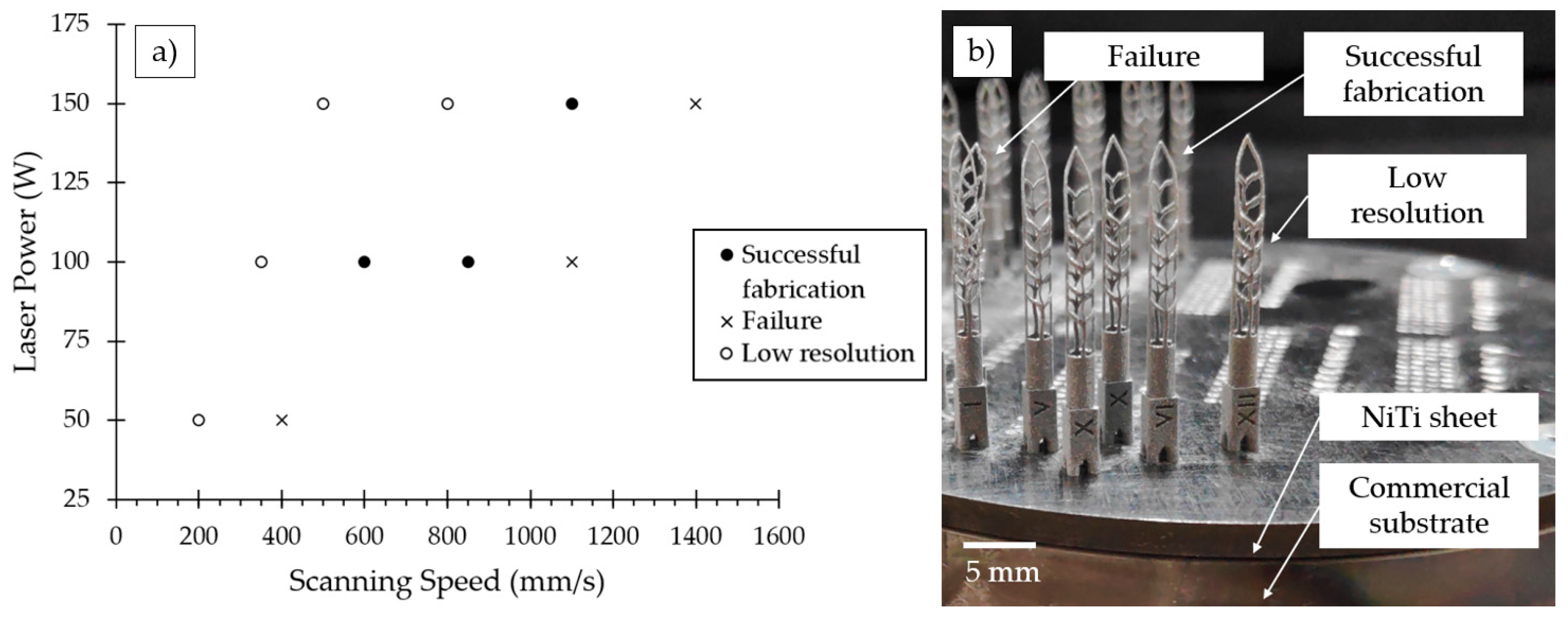

3.3. High Resolution Fabrication of Self-Adjusting Files

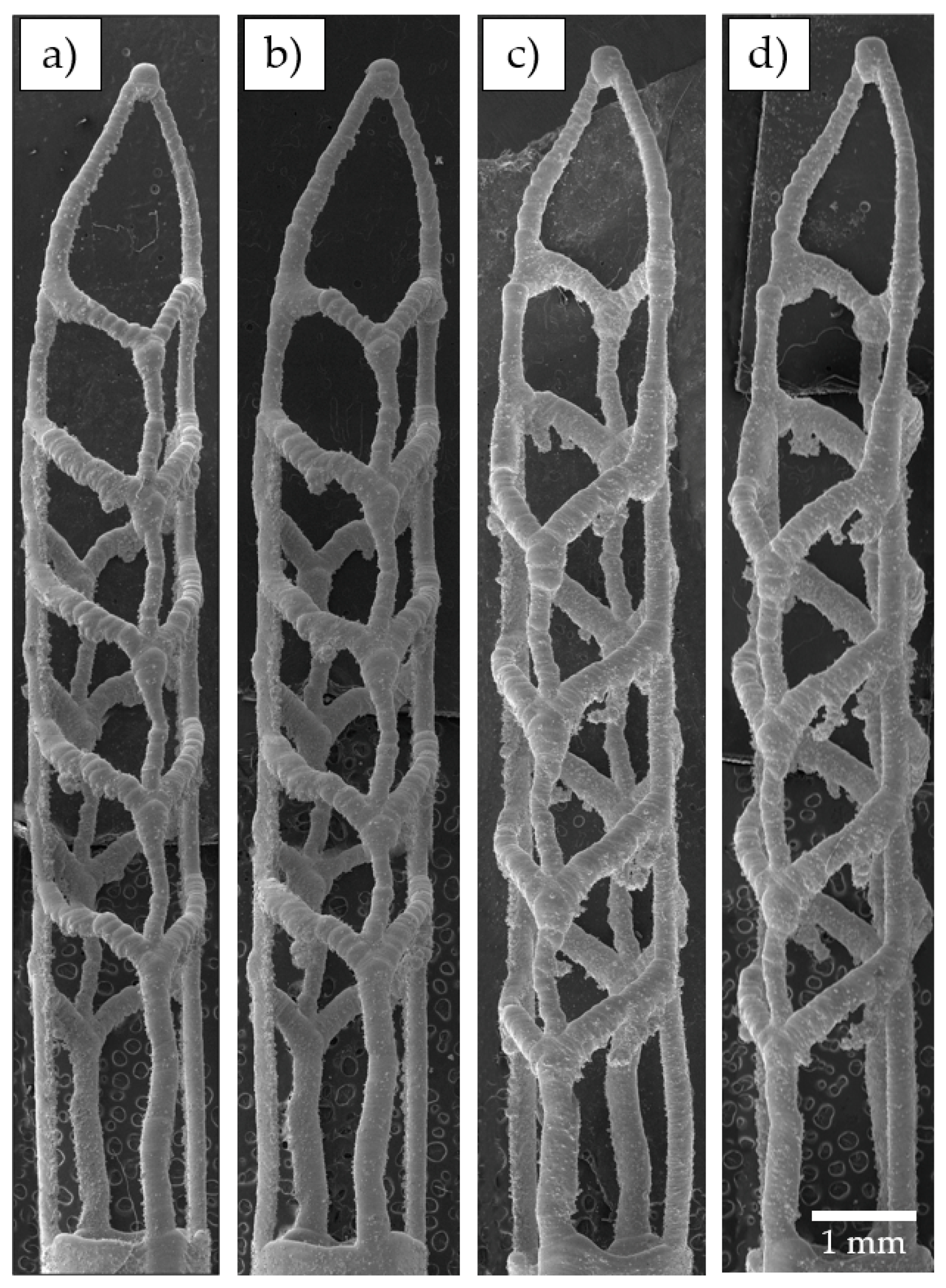

3.4. Characterization of SAF Sample Made with Optimal Process Parameters

4. Conclusions

- (1)

- Within this work the feasibility of manufacturing endodontic Self-Adjusted Files from Nickel-Titanium shape memory alloy was demonstrated via conventional LPBF technology with found optimal process parameters including laser power of 100 W, scanning speed of 850 mm/s, and layer thickness of 20 μm.

- (2)

- The key factor limiting the resolution of LPBF technology is the melt pool dimensions; if the technological window for raw material is wide enough, the combination resulting in the smallest width and depth of the melt pool will be required for the manufacturing of objects with small feature size, i.e., endodontic files, strut-based structures, coronary stents, porous micro-implants, etc. The minimum wall thickness of 54 ± 10 μm was achieved for the NiTi powder which is close to the laser beam diameter.

- (3)

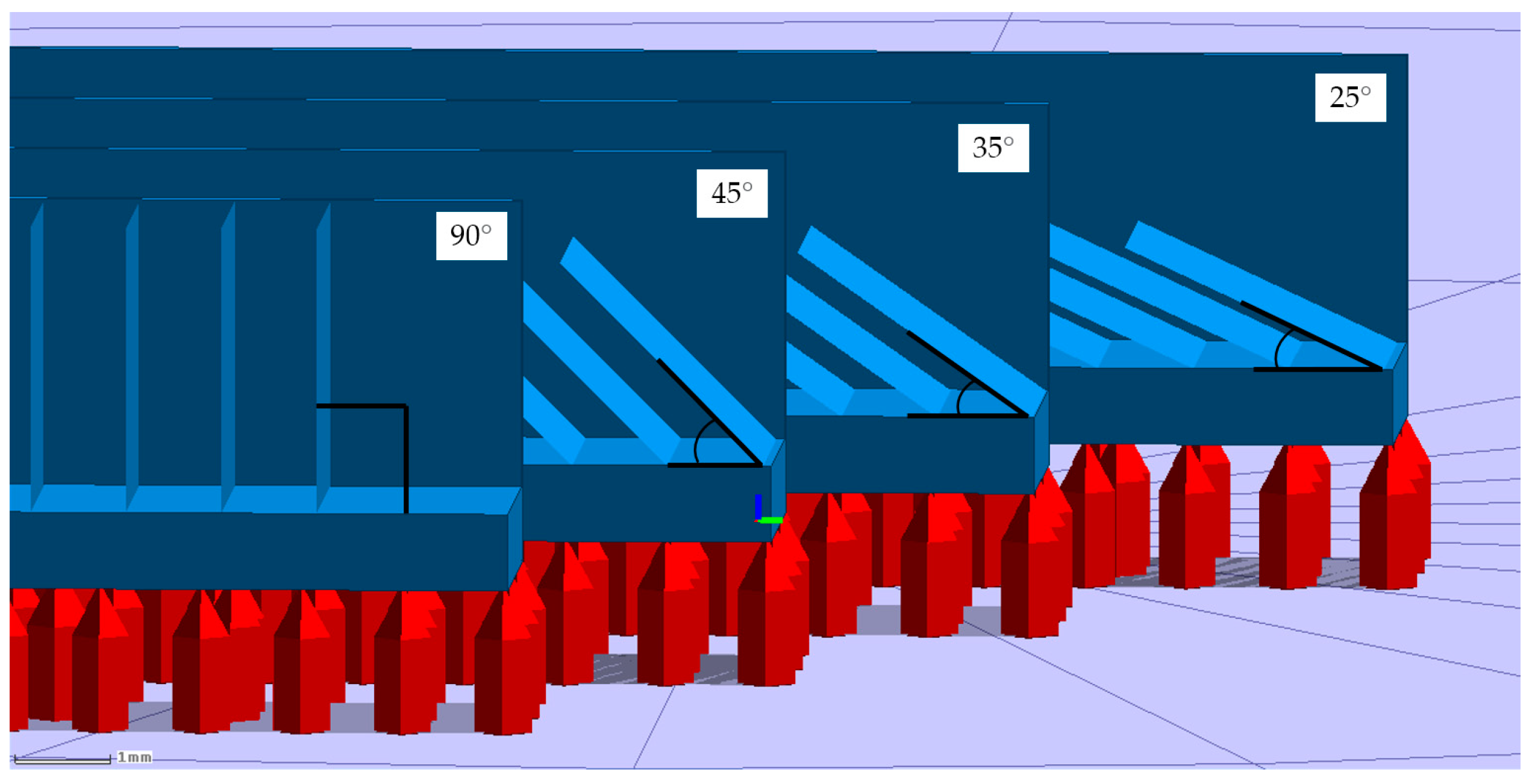

- Accuracy and resolution of final parts can be increased by special algorithms to slicing software for implementation of scanning strategy based on single vectors without contours and subsequent filling of hatch lines. In single track based manufacturing inclined angle of the part plays an important role. It was demonstrated that the critical value for micro objects is dependent on layer thickness and linear energy density. Successful fabrication of micro object with an inclined angle of 24° was demonstrated which is significantly lower than the conventional limit of 45°.

- (4)

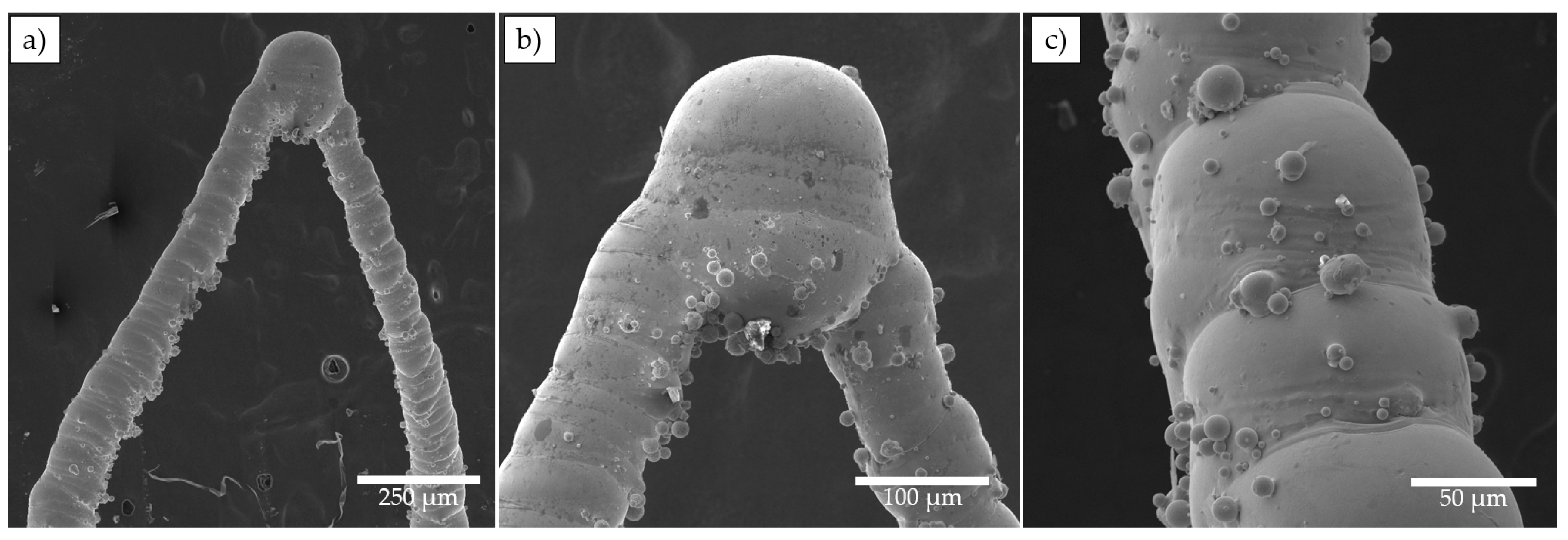

- Powder adhesion and the layering effect inherent to LPBF technology have a higher impact on the manufacturing of the micro object with high resolution. Such surface irregularities are inevitable; however, post-treatment can be applied to decrease the roughness of the part elements and the diameter of the struts.

- (5)

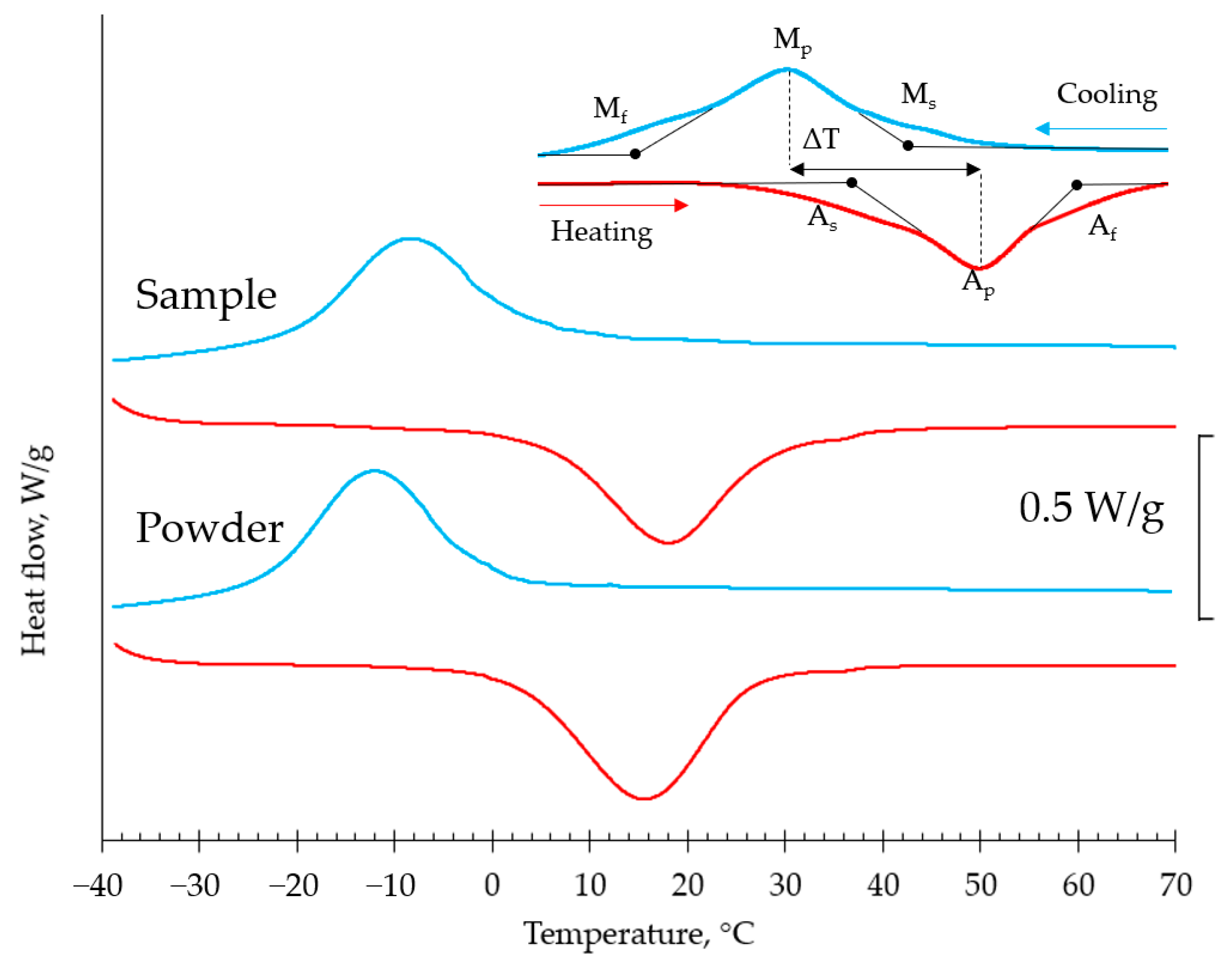

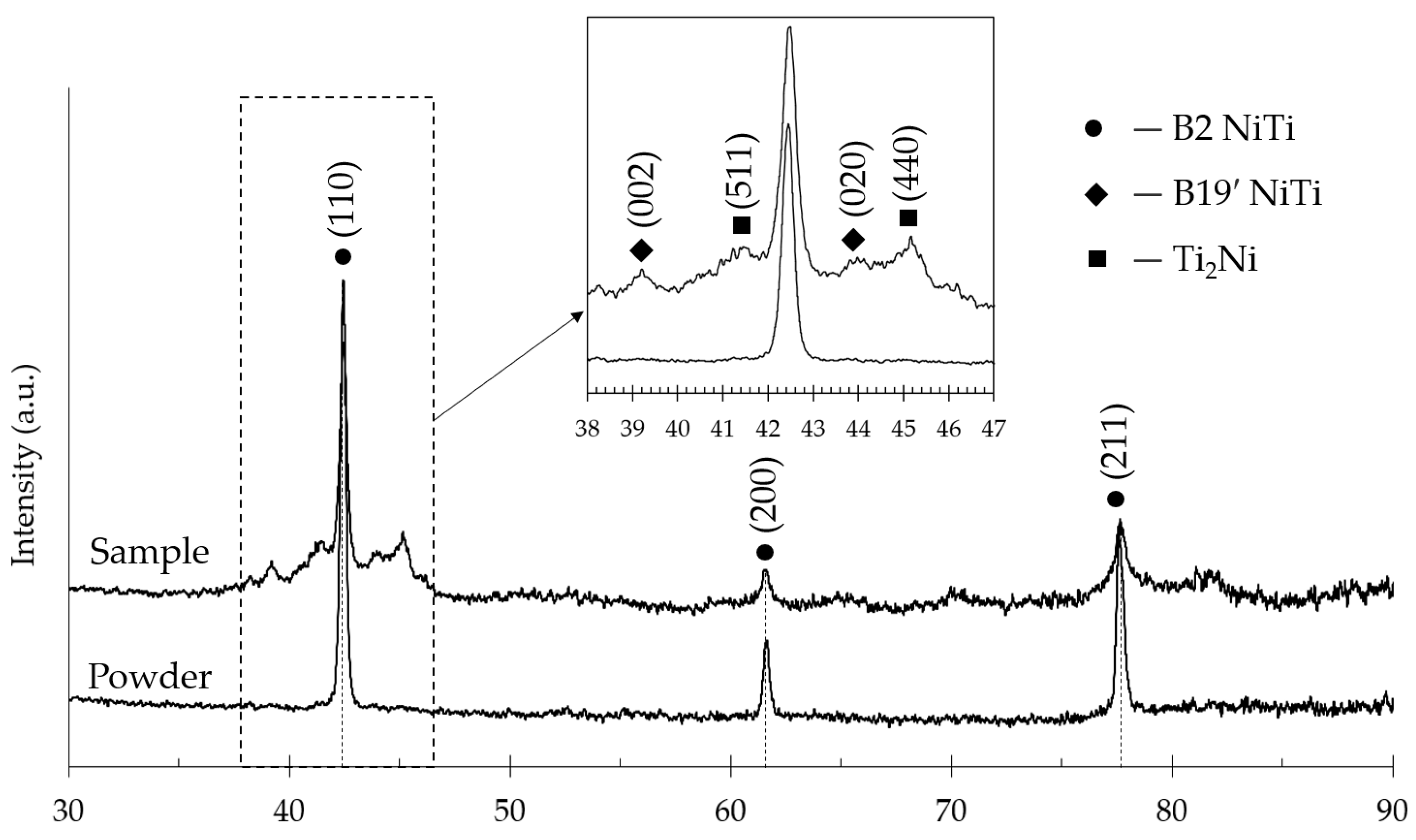

- The martensite phase transformation of the SAF sample produced via LPBF was shifted to higher temperatures in comparison with the powder. Such change can be attributed to the Ni evaporation and formation of the Ti2Ni phase that was detected by the XRD analysis.

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Metzger, Z. The Self-Adjusting File System. J. Conserv. Dent. 2013, 7, 189–210. [Google Scholar]

- Bansal, K. SAF: Paving A Way to Minimal Invasive Endodontics. Int. Dent. J. Stud. Res. 2015, 3, 144–149. [Google Scholar]

- Solomonov, M. Eight Months of Clinical Experience with the Self-Adjusting File System. J. Endod. 2011, 37, 881–887. [Google Scholar] [CrossRef] [PubMed]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 9781493921126. [Google Scholar]

- Qu, S.; Ding, J.; Song, X. Achieving Triply Periodic Minimal Surface Thin-Walled Structures by Micro Laser Powder Bed Fusion Process. Micromachines 2021, 12, 705. [Google Scholar] [CrossRef] [PubMed]

- Gao, P.; Wang, Z.; Zeng, X. Effect of Process Parameters on Morphology, Sectional Characteristics and Crack Sensitivity of Ti-40Al-9V-0.5Y Alloy Single Tracks Produced by Selective Laser Melting. Int. J. Light. Mater. Manuf. 2019, 2, 355–361. [Google Scholar] [CrossRef]

- Taheri Andani, M.; Saedi, S.; Turabi, A.S.; Karamooz, M.R.; Haberland, C.; Karaca, H.E.; Elahinia, M. Mechanical and Shape Memory Properties of Porous Ni50.1Ti49.9 Alloys Manufactured by Selective Laser Melting. J. Mech. Behav. Biomed. Mater. 2017, 68, 224–231. [Google Scholar] [CrossRef]

- Gruber, K.; Smolina, I.; Kasprowicz, M.; Kurzynowski, T. Evaluation of Inconel 718 Metallic Powder to Optimize the Reuse of Powder and to Improve the Performance and Sustainability of the Laser Powder Bed Fusion (Lpbf) Process. Materials 2021, 14, 1538. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Elambasseril, J.; McMillan, M.; Chirent, T.; Sun, Y.; Qian, M.; Easton, M.; Brandt, M. Selective Laser Melting (SLM) of AlSi12Mg Lattice Structures. Mater. Des. 2016, 98, 344–357. [Google Scholar] [CrossRef]

- Xiao, Z.; Yang, Y.; Xiao, R.; Bai, Y.; Song, C.; Wang, D. Evaluation of Topology-Optimized Lattice Structures Manufactured via Selective Laser Melting. Mater. Des. 2018, 143, 27–37. [Google Scholar] [CrossRef]

- Orla, A.; Mcgee, M.; Geraghty, S.; Hughes, C.; Jamshidi, P.; Kenny, D.P.; Attallah, M.M.; Lally, C. An Investigation into Patient-Specific 3D Printed Titanium Stents and the Use of Etching to Overcome Selective Laser Melting Design Constraints. bioRxiv 2022, 134, 105388. [Google Scholar] [CrossRef]

- Sabahi, N.; Chen, W.; Wang, C.H.; Kruzic, J.J.; Li, X. A Review on Additive Manufacturing of Shape-Memory Materials for Biomedical Applications. JOM 2020, 72, 1229–1253. [Google Scholar] [CrossRef]

- Wang, D.; Yang, Y.; Liu, R.; Xiao, D.; Sun, J. Study on the Designing Rules and Processability of Porous Structure Based on Selective Laser Melting (SLM). J. Mater. Process. Technol. 2013, 213, 1734–1742. [Google Scholar] [CrossRef]

- Wang, D.; Yang, Y.; Yi, Z.; Su, X. Research on the Fabricating Quality Optimization of the Overhanging Surface in SLM Process. Int. J. Adv. Manuf. Technol. 2013, 65, 1471–1484. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Smurov, I. Parametric Analysis of the Selective Laser Melting Process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Caprio, L.; Demir, A.G.; Previtali, B. Comparative Study between CW and PW Emissions in Selective Laser Melting. J. Laser Appl. 2018, 30, 032305. [Google Scholar] [CrossRef]

- Wu, Z.; Narra, S.P.; Rollett, A. Exploring the Fabrication Limits of Thin-Wall Structures in a Laser Powder Bed Fusion Process. Int. J. Adv. Manuf. Technol. 2020, 110, 191–207. [Google Scholar] [CrossRef]

- Lesyk, D.; Lymar, O.; Dzhemelinkyi, V. Surface Characterization of the Cobalt-Based Alloy Stents Fabricated by 3D Laser Metal Fusion Technology. Lect. Notes Netw. Syst. 2021, 233, 357–364. [Google Scholar] [CrossRef]

- Paul, B.; Lode, A.; Placht, A.M.; Voß, A.; Pilz, S.; Wolff, U.; Oswald, S.; Gebert, A.; Gelinsky, M.; Hufenbach, J. Cell-Material Interactions in Direct Contact Culture of Endothelial Cells on Biodegradable Iron-Based Stents Fabricated by Laser Powder Bed Fusion and Impact of Ion Release. ACS Appl. Mater. Interfaces 2022, 14, 439–451. [Google Scholar] [CrossRef]

- Maffia, S.; Finazzi, V.; Berti, F.; Migliavacca, F.; Petrini, L.; Previtali, B.; Demir, A.G. Selective Laser Melting of NiTi Stents with Open-Cell and Variable Diameter. Smart Mater. Struct. 2021, 18, 119–123. [Google Scholar] [CrossRef]

- Momma, C.; Knop, U.; Nolte, S. Laser Cutting of Slotted Tube Coronary Stents–State-of-the-Art and Future Developments. Prog. Biomed. Res. 1999, 4, 39–44. [Google Scholar]

- Mwangi, J.W.; Nguyen, L.T.; Bui, V.D.; Berger, T.; Zeidler, H.; Schubert, A. Nitinol Manufacturing and Micromachining: A Review of Processes and Their Suitability in Processing Medical-Grade Nitinol. J. Manuf. Process. 2019, 38, 355–369. [Google Scholar] [CrossRef]

- Elahinia, M.; Shayesteh Moghaddam, N.; Taheri Andani, M.; Amerinatanzi, A.; Bimber, B.A.; Hamilton, R.F. Fabrication of NiTi through Additive Manufacturing: A Review. Prog. Mater. Sci. 2016, 83, 630–663. [Google Scholar] [CrossRef]

- Kaya, E.; Kaya, İ. A Review on Machining of NiTi Shape Memory Alloys: The Process and Post Process Perspective. Int. J. Adv. Manuf. Technol. 2019, 100, 2045–2087. [Google Scholar] [CrossRef]

- Chernyshikhin, S.V.; Firsov, D.G.; Shishkovsky, I.V. Selective Laser Melting of Pre-Alloyed NiTi Powder: Single-Track Study and FE Modeling with Heat Source Calibration. Materials 2021, 14, 7486. [Google Scholar] [CrossRef] [PubMed]

- Dzogbewu, T.C.; du Preez, W.B. Additive Manufacturing of Ti-Based Intermetallic Alloys: A Review and Conceptualization of a next-Generation Machine. Materials 2021, 14, 4317. [Google Scholar] [CrossRef]

- Caprio, L.; Demir, A.G.; Chiari, G.; Previtali, B. Defect-Free Laser Powder Bed Fusion of Ti–48Al–2Cr–2Nb with a High Temperature Inductive Preheating System. J. Phys. Photonics 2020, 2, 024001. [Google Scholar] [CrossRef]

- Kaplanskii, Y.Y.; Levashov, E.A.; Korotitskiy, A.V.; Loginov, P.A.; Sentyurina, Z.A.; Mazalov, A.B. Influence of Aging and HIP Treatment on the Structure and Properties of NiAl-Based Turbine Blades Manufactured by Laser Powder Bed Fusion. Addit. Manuf. 2020, 31, 100999. [Google Scholar] [CrossRef]

- Elahinia, M.H.; Hashemi, M.; Tabesh, M.; Bhaduri, S.B. Manufacturing and Processing of NiTi Implants: A Review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Fu, J.; Qu, S.; Ding, J.; Song, X.; Fu, M.W. Comparison of the Microstructure, Mechanical Properties and Distortion of Stainless Steel 316 L Fabricated by Micro and Conventional Laser Powder Bed Fusion. Addit. Manuf. 2021, 44, 102067. [Google Scholar] [CrossRef]

- Sutton, A.T.; Kriewall, C.S.; Leu, M.C.; Newkirk, J.W.; Sutton, A.T.; Kriewall, C.S.; Leu, M.C.; Newkirk, J.W. Powder Characterisation Techniques and Effects of Powder Characteristics on Part Properties in Powder-Bed Fusion Processes. Virtual Phys. Prototyp. 2016, 12, 3–29. [Google Scholar] [CrossRef]

- Kassym, K.; Perveen, A. Atomization Processes of Metal Powders for 3D Printing. Mater. Today Proc. 2019, 26, 1727–1733. [Google Scholar] [CrossRef]

- Altug-Peduk, G.S.; Dilibal, S.; Harrysson, O.; Ozbek, S.; West, H. Characterization of Ni–Ti Alloy Powders for Use in Additive Manufacturing. Russ. J. Non-Ferr. Met. 2018, 59, 433–439. [Google Scholar] [CrossRef]

- Shinkaryov, A.S.; Cherkasova, M.V.; Pelevin, I.A.; Ozherelkov, D.Y.; Chernyshikhin, S.V.; Kharitonova, N.A.; Gromov, A.A.; Nalivaiko, A.Y. Aluminum Powder Preparation for Additive Manufacturing Using Electrostatic Classification. Coatings 2021, 11, 629. [Google Scholar] [CrossRef]

- Pelevin, I.A.; Burmistrov, M.A.; Ozherelkov, D.Y.; Shinkaryov, A.S.; Chernyshikhin, S.V.; Gromov, A.A.; Nalivaiko, A.Y. Laser Powder Bed Fusion of Chromium Bronze Using Recycled Powder. Materials 2021, 14, 3644. [Google Scholar] [CrossRef] [PubMed]

- Brika, S.E.; Letenneur, M.; Dion, C.A.; Brailovski, V. Influence of Particle Morphology and Size Distribution on the Powder Flowability and Laser Powder Bed Fusion Manufacturability of Ti-6Al-4V Alloy. Addit. Manuf. 2020, 31, 100929. [Google Scholar] [CrossRef]

- Vock, S.; Klöden, B.; Kirchner, A.; Weißgärber, T.; Kieback, B. Powders for Powder Bed Fusion: A Review. Prog. Addit. Manuf. 2019, 4, 383–397. [Google Scholar] [CrossRef]

- Bonesso, M.; Rebesan, P.; Gennari, C.; Mancin, S.; Dima, R.; Pepato, A.; Calliari, I. Effect of Particle Size Distribution on Laser Powder Bed Fusion Manufacturability of Copper. BHM Berg Hüttenmännische Mon. 2021, 166, 256–262. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Yadroitsev, I.; Bertrand, P.; Smurov, I. Model of Radiation and Heat Transfer in Laser-Powder Interaction Zone at Selective Laser Melting. J. Heat Transf. 2009, 131. [Google Scholar] [CrossRef]

- Tan, C.; Li, S.; Essa, K.; Jamshidi, P.; Zhou, K.; Ma, W.; Attallah, M.M. Laser Powder Bed Fusion of Ti-Rich TiNi Lattice Structures: Process Optimisation, Geometrical Integrity, and Phase Transformations. Int. J. Mach. Tools Manuf. 2019, 141, 19–29. [Google Scholar] [CrossRef]

- Nayak, S.K.; Mishra, S.K.; Paul, C.P.; Jinoop, A.N.; Bindra, K.S. Effect of Energy Density on Laser Powder Bed Fusion Built Single Tracks and Thin Wall Structures with 100 Μm Preplaced Powder Layer Thickness. Opt. Laser Technol. 2020, 125, 106016. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Van Humbeeck, J.; Kruth, J.P. Laser Additive Manufacturing of Bulk and Porous Shape-Memory NiTi Alloys: From Processes to Potential Biomedical Applications. MRS Bull. 2016, 41, 765–774. [Google Scholar] [CrossRef]

- Frenzel, J.; George, E.P.; Dlouhy, A.; Somsen, C.; Wagner, M.F.X.; Eggeler, G. Influence of Ni on Martensitic Phase Transformations in NiTi Shape Memory Alloys. Acta Mater. 2010, 58, 3444–3458. [Google Scholar] [CrossRef]

- Saedi, S.; Turabi, A.S.; Andani, M.T.; Haberland, C.; Elahinia, M.; Karaca, H. Thermomechanical Characterization of Ni-Rich NiTi Fabricated by Selective Laser Melting. Smart Mater. Struct. 2016, 25, 035005. [Google Scholar] [CrossRef]

- Shayesteh Moghaddam, N.; Saedi, S.; Amerinatanzi, A.; Hinojos, A.; Ramazani, A.; Kundin, J.; Mills, M.J.; Karaca, H.; Elahinia, M. Achieving Superelasticity in Additively Manufactured NiTi in Compression without Post-Process Heat Treatment. Sci. Rep. 2019, 9, 41. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Sample Name | Laser Power, W | Scanning Speed, mm/s | Linear Energy Density, J/mm |

|---|---|---|---|

| P50V200 | 50 | 200 | 0.25 |

| P50V400 | 50 | 400 | 0.13 |

| P50V600 | 50 | 600 | 0.08 |

| P50V800 | 50 | 800 | 0.06 |

| P50V1000 | 50 | 1000 | 0.05 |

| P100V350 | 100 | 350 | 0.29 |

| P100V600 | 100 | 600 | 0.17 |

| P100V850 | 100 | 850 | 0.12 |

| P100V1100 | 100 | 1100 | 0.09 |

| P100V1350 | 100 | 1350 | 0.07 |

| P150V500 | 150 | 500 | 0.30 |

| P150V800 | 150 | 800 | 0.19 |

| P150V1100 | 150 | 1100 | 0.14 |

| P150V1400 | 150 | 1400 | 0.11 |

| P150V1700 | 150 | 1700 | 0.09 |

| Sample Name | Transformation Temperatures (°C) | ||||||

|---|---|---|---|---|---|---|---|

| Ms | Mp | Mf | As | Ap | Af | ΔT | |

| NiTi raw powder | −1.1 | −12.2 | −22.8 | 2.5 | 15.5 | 26.3 | 27.7 |

| P100V850 sample | 3.8 | −8.5 | −20.2 | 4.7 | 18.3 | 29.7 | 26.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chernyshikhin, S.V.; Pelevin, I.A.; Karimi, F.; Shishkovsky, I.V. The Study on Resolution Factors of LPBF Technology for Manufacturing Superelastic NiTi Endodontic Files. Materials 2022, 15, 6556. https://doi.org/10.3390/ma15196556

Chernyshikhin SV, Pelevin IA, Karimi F, Shishkovsky IV. The Study on Resolution Factors of LPBF Technology for Manufacturing Superelastic NiTi Endodontic Files. Materials. 2022; 15(19):6556. https://doi.org/10.3390/ma15196556

Chicago/Turabian StyleChernyshikhin, Stanislav V., Ivan A. Pelevin, Farzad Karimi, and Igor V. Shishkovsky. 2022. "The Study on Resolution Factors of LPBF Technology for Manufacturing Superelastic NiTi Endodontic Files" Materials 15, no. 19: 6556. https://doi.org/10.3390/ma15196556